Course Introduction

Course Introduction

Core Standards of the Course

Strand 1

Students will review basic sewing knowledge.

Standard 1

Review sewing tools knowledge and machine functions. (Refer to Sewing Construction 1 or Sports & Outdoor Product Design 1) Sewing machine use and maintenance.

Strand 2

Students will develop machine knowledge and skills.

-

Identify various specialty presser feet.

-

Identify specialty needles.

-

Identify specialty threads.

- Quilting: a strong cotton thread with a waxy coating to prevent tangling when used in hand- quilting. It is not appropriate for use in sewing machine.

- Heavy duty: Slightly heavier than all-purpose thread; to be used for prominent topstitching.

- Embroidery: Decorative thread offered in a wide variety of vibrant colors. Silky, lustrous, and versatile, it is weaker than regular sewing thread and should not be used for construction. It is used for decorative stitches.

- Metallic: Add glitter and they are durable. All-purpose thread should be used on the bobbin; use metallic in upper looper on a serger.

- Elastic: Used for stretching shirring; usually wound by hand onto the bobbin. The bobbin tension must be adjusted when using this type of thread.

- Serger: lighter weight than all-purpose sewing machine thread.

-

Identify specialty stitches.

Standard 2

Operate, thread, and maintain a serger.

-

Identify the needle stitch plate, feed dogs/system, presser foot, thread tensions, presser foot lever/lifter, handwheel, stitch length control, knives and loopers (overcast on the serger).

-

Thread, operate, and care for serger according to machine manual (e.g., clean, oil).

-

Creates two types of stitches

-

Needles and looper work together to create a straight and flatlock stitches.

Standard 3

Use pressing tools to create a professional product.

-

Incorporate the practice of "press as you sew."

-

Use pressing equipment.

- Tailor's ham: for pressing curved areas of clothing (darts, shoulders, collars, etc.)

- Sleeve board: narrow board for sleeves.

- Seam roll: oblong for long, project like sleeves.

- Point presser: for narrow, hard-to-reach areas of collars, belts, cuffs, corners and points.

- Pressing cloth: prevents scorching/melting of fabric.

-

Identify and use appropriate temperature settings for various fabrics with different fiber content.

Performance Skills

Thread/operate and care for the serger.

Strand 3

Students will distinguish the different types of fabric and fiber characteristics.

Standard 1

Identify and review basic fibers.

-

General Characteristics: Natural fiber characteristics comes from plant and animals, moisture absorbent, more expensive.

- Cotton: Plant source

- Pros - absorbent, comfortable, durable, easy to launder, stronger wet than dry.

- Cons - wrinkles, shrinks, mildews.

- Linen: Plant source (flax)

- Pros - absorbent, natural luster, quick drying.

- Cons - wrinkles, frays, little stretch, mildews.

- Silk: Animal source (silkworm cocoon)

- Pros - absorbent, natural luster, insulating, strong, resilient.

- Cons - degrades and yellows from age and sunlight, weaker wet than dry, water marks.

- Wool: Animal source (fur)

- Pros - absorbent, strong, elastic, flame resistant, wrinkle resistant.

- Cons - shrinks when laundered improperly, bleaches with sunlight, damaged by moths.

- Cotton: Plant source

Standard 2

Identify manufactured fibers and their characteristics.

-

General characteristics: made from chemical processes (some made from natural elements mixed with chemicals while other are made completely from non-natural substances).

- Nylon: Chemical sources

- Pros - strong, water repellent, colorfast, abrasion resistant.

- Cons - frays easily, non-recyclable.

- Polyester: Chemical source

- Pros - good shape retention, easy to launder, wrinkle resistant, colorfast,blends well with other fibers.

- Cons - retains oily stains, pills, builds static.

- Rayon: Cellulose source

- Pros - soft and comfortable, drapes well, blends well with other fibers, dyeswell.

- Cons - shrinks, poor shape retention, wrinkles, dry clean only.

- Spandex: Chemical source

- Pros - very elastic, adds stretch when blended with other fibers, resistant to oils and outdoor elements (sun, sea and sand).

- Cons - shrinks, damaged by heat, can be difficult to sew.

- Bamboo - Cellulose source

- Pros - soft, strong, water absorbent, renewable.

- Cons - wrinkles, takes longer to dry and yellow with time.

- Nylon: Chemical sources

Standard 3

Identify various types of fabric construction.

-

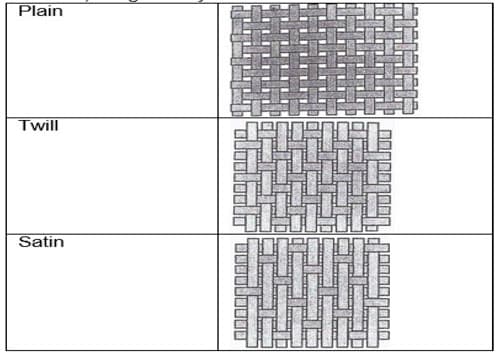

Classify basic weaves.

- Plain: yarns interlace at right angles, passing alternately over and under each other; soft, durable, easy to sew, wrinkles easily.

- Twill: one yarn passes over two or more yarns to create a diagonal pattern; strong, wrinkle resistant, hides soil.

- Satin: yarns float over four or more yarns, then pass under one; shiny, smooth surface, snags easily.

-

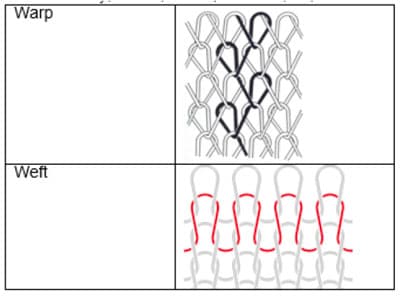

Classify basic knits

-

Classify non-woven fabrics (e.g., felt and bonded).

Standard 4

Identify specific fabrics utilized in outdoor soft goods.

-

Ripstop nylon: nylon fabric made with a special reinforcing technique that makes it resistant to tearing and ripping.

-

Canvas: extremely durable plain-woven fabric.

-

Vinyl: non-woven plastic fabric.

-

Leather: the skin of an animal that has been tanned and treated.

-

Two-way stretch: stretches from selvage to selvage.

-

Four-way stretch: stretches both along the lengthwise and crosswise grain.

-

Polar fleece: soft napped insulating fabric made from polyester.

-

Sweatshirt fleece: type of jersey fabric with plain knit stitches on the front and purl knit stitches on the back; stretch factor makes it popular.

-

Rib knit: double knit fabric where the rib wales alternate on the face and back of the fabric.

-

Flannel: woven fabric made of cotton where the surface has been slightly brushed to create a soft napped fabric.

-

Neoprene: soft, flexible, and durable synthetic sponge rubber that is water resistant and stretchable.

Performance Skills

Participate in a fiber identification lab. Use different ways of identifying fibers; for example, burn test, chemical test (acetone or bleach), or microscope observations.

Strand 4

Students will demonstrate pre-construction techniques at the intermediate level.

Standard 1

Students will independently take measurements, determine pattern size and make pattern alterations.

-

Determine pattern size based on body measurements and finished garment measurements. Look at finished garment measurements on pattern envelope and pattern pieces, then compare to body measurements to choose a good fit.

-

Review relationship between body measurements and pattern measurements and the use of ease.

- Wearing ease: amount added to a person's body measurements so one canmove in a garment.

- Design ease: any amount of ease beyond the basic wearing ease that creates the style of a garment.

- Layering ease: amount of ease added to clothing that will be worn over other clothing.

- Negative ease: will measure smaller than actual body measurements but will stretch to fit comfortably.

Standard 2

Apply pattern preparation techniques.

-

Review basic pattern symbols (e.g., straight of grain arrows, notches, pattern markings, buttons and buttonholes, place on fold line, sizing lines, adjustment lines).

-

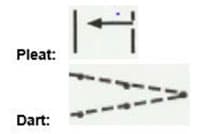

Identify pattern symbols (e.g., pleat, dart, finished garment measurements, center front or back).

-

Finished garment measurements: measurements of the garment after it is completed

-

Center front and back: where the center of the garment front or back is located.

-

Review pattern placement and layout on fabric (e.g., straight of grain is always parallel to the selvage; place on fold should be placed directly on the fold of the fabric; allows the garment to hang straight).

-

Review one-way directional/nap layout (e.g., all pattern pieces must face the same direction; tops of the pattern pieces should be at the top of the direction of the design or nap).

Standard 3

Student will use appropriate marking techniques.

Strand 5

Students will use correct sewing construction techniques at the intermediate level.

Standard 1

Students will use correct sewing construction techniques at the intermediate level.

-

Identify stitching techniques and their applications.

- Dart: The goal is to sew a dart with a point that is as smooth as possible. Stitch from the wide end to the tip, do not back stitch at the point. To secure, leave long threads and tie.

- Ease stitching: There are three ways to ease a seam: (1) gather before sewing the seam, (2) stretch the shorter seam as you sew the unequal layers together, or (3) let the machine ease the longer edge as the layers move under the presser foot.

- Gather: Tiny, soft folds of fabric that form when a larger piece of fabric is sewnto smaller piece. The fabric should determine the best method of gathering touse. The goal is to create small, evenly spaced folds of fabric along the gathered area. There are four basic ways to gather: (1) rows of basting stitches, (2) machine couch a cord, (3) use a ruffler attachment or gathering foot, and (4) zigzag over clear elastic.

- Pleat: All pleats involve folding fabric, and each folding strategy produces a different type of pleat. (e.g., knife pleat, box pleat, inverted pleat)

- Tuck: A stitched fold of fabric that is usually decorative but can also be used to add shape to a garment; formed so that the fold and stitching show on the right side of the fabric.

- Topstitching: A row of evenly spaced straight stitches visible on the right side ofa garment; usually aligned parallel to an edge or a seam. Typical distance is 1/4"to 3/8"; however, it usually is a matter of taste.

- Understitching: A technique when seam allowances are sewn to a fabric layer to help keep the fabric from rolling to the right side of the garment; invisible from the right side of the garment. Grade and clip seam allowances before understitching. Press seam allowances toward the facing.

- Stitch in the ditch: Refers to machine stitching that is sewn in the "ditch" of a seam so that it sinks into the seam and stays out of sight.

- Stay stitching: A row of permanent, straight stitches sewn on a single layer to prevent stretching in key areas when you're handling the garment during the construction process. The stitching should be done just inside the seam allowance. (1/2" from the cut edge if seam allowances are 5/8") No back stitch is necessary.

- Blind Hem: The finished edge on the bottom of a garment sewn so that the stitching is invisible.

Standard 2

Practice correct application techniques for applying interfacing and attaching facings or collars.

-

Interfacing can fulfill the following functions.

-

Select and apply appropriate interfacing. (fusible, non-fusible)

- Sew-in/non-fusible interfacing must be anchored to the garment with stitches, either sewn into a seam or sewn onto a layer of fabric before being sewn into the garment. To apply, sew the interfacing to the wrong side of fabric within the seam allowance.

- Fusible interfacing is attached to the fashion fabric with glue activated by heat from the iron. To apply non-fusible, use heat, moisture and a press cloth. Followthe manufacturer's instructions.

- Choose between sew-in/non-fusible and fusible based on the project fabric, the garment's requirement and preference.

-

Demonstrate techniques associated with attaching facings or collars.

- Facings used to finish edges at necklines, armholes, front and back openings, hems, vents, and slits. Facings add support, prevent the edge from stretching and ensure a flat, crisp outer edge.

- Three types of collars:

- Flat: falling or lying flat on the shoulders. (i.e. Golf shirt, Sailor Collar)

- Rolled: Stands up and falls on the neck. (. i.e. Dress shirt, Turtleneck)

- Standing: Stands up against neck. (i.e. Mandarin, Banded)

Standard 3

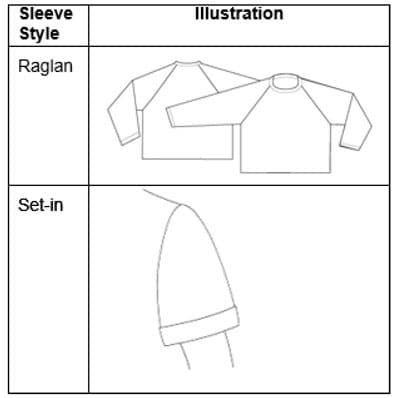

Identify each of the following sleeves:

-

Raglan sleeves: (two-piece and one-piece) join the bodice in a diagonal seam that extends from the neckline to the side seam.

-

Set-in sleeves: Joined to the garment bodice at a seam that circles over the shoulder and under the arm. A well-made set-in sleeve meets at the shoulder in a pucker-free, smooth, curved seam. Two methods of construction: closed/round method and open/flat method.

-

Two methods of construction: closed/round method and open/flat method.

Standard 4

Identify each of the following zipper applications and construct one or more.

-

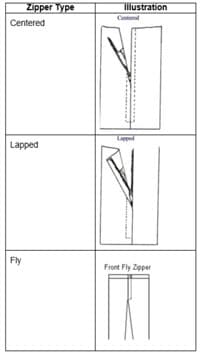

Centered zippers are found on a variety of garments, including dresses, skirts and pants. Centered zippers align the seam over the zipper teeth and the zipper tape is covered by symmetrical overlaps on each side. Parallel lines of top stitching flank the seam.

-

Lapped zippers are sewn to completely hide the zipper under a flap of fabric, and are found in skirts, pants, and center backs of dresses.

-

Fly zippers are used in pants. Women's garments lap right over left, and men's garments lap left over right.

-

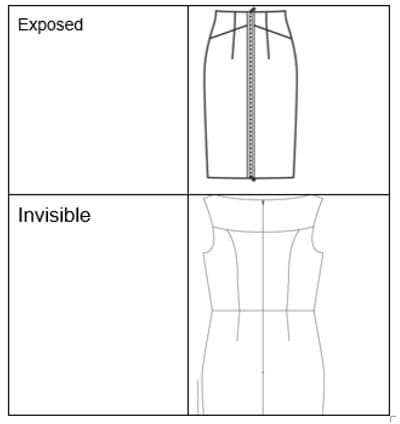

Exposed zippers are sewn directly on the outside of the garment. The zipper tape becomes a decorative feature. When installing an exposed zipper, turn the seam allowances to the right side, topstitch the zipper over the seam allowance to cover the fabric edge.

-

Invisible zippers, when inserted correctly, are unnoticeable except for the zipper pull. They are incredibly flexible and soft, making them ideal for fine fabrics.

Standard 5

Identify types and complete correct application of hems.

-

Identify steps of hem preparation. (i.e., appropriate length and width, reduce bulk, ease, pressing)

-

Apply correct edge finishes. (e.g., clean finished, zigzag, serged)

-

Complete one or more of the following hemming techniques: hand stitched hems, double fold hem, machine blind hem, rolled hem.

Performance Skills

Complete all of the following skills as part of the course. A minimum of 8 skills need to be included as part of an apparel or accessory/personal item project.

-

Stay stitching

-

Trimming

-

Grading

-

Clipping or notching

-

Understitching

-

Darts, tucks, pleats, or gathers

-

Select and apply interfacing

-

Sew one or more correct sleeve style (i.e., set in, raglan)

-

Demonstrate one or more correct zipper applications

-

Attach one or more appropriate closure (i.e., hook and eye, snap, pant/skirt hook

-

Complete two of the following hemming techniques: hand-stitched hems, double fold hem, machine blind hem, rolled hem or other hemming technique

-

Demonstrate the application of bias tape

Performance Skills

Use commercially prepared directions/guide sheets.

Workplace Skills

Students will develop professional and interpersonal skills needed for success in the fashion industry.

-

Determine the difference between hard skills and soft skills.

-

Identify soft skills needed in the workplace

UTAH EDUCATION NETWORK

UTAH EDUCATION NETWORK

Justin

Justin Braxton

Braxton Dani

Dani Kayla

Kayla Katie

Katie Matthew

Matthew Rob

Rob Val

Val