Course Introduction

Course Introduction

Core Standards of the Course

Strand 1

Students will explore the characteristics of natural (cotton, hemp, linen, silk, wool) and manufactured fibers (aramid, lyocell, nylon, olefin, polyester, spandex) in the sports and outdoor industry.

Standard 1

Review basic characteristics of natural and manufactured fibers (see prerequisite courses)

Standard 2

Investigate the physical properties of natural and manufactured fibers.

-

Fiber structure

- Length - Staple or filament fibers influences Strength and hand

- Diameter - Thickness of the fiber influences stiffness, wrinkle resistance and transparency

- Shape - Cross-sectional shape impacts luster, bulk, body, texture, soiling and hand

- Surface contour - the outer surface of the fiber

- Crimp - refers to the waves, bends, twists, and coils

-

Hand - How the fiber feels

-

Cover - The ability of a fiber to hide/protect what is beneath

Standard 3

Performance properties of natural and manufactured fibers.

-

Absorbency - The ability to take up moisture from the body or environment (hydrophilic/hydrophobic)

-

Soiling - The ability to resist dirt and oils (oleophilic/oleophobic)

-

Abrasion - The ability to withstand rubbing during use (pilling)

-

Wicking - The ability to transfer moisture along its surface

-

Dimensional stability - The ability to maintain the original shape neither shrinking nor stretching

-

Flammability - The ability to ignite or burn (flammable, flame-resistant, and flame proof)

-

Resiliency - capability of a material to spring back to shape after being creased, twisted or distorted

Strand 2

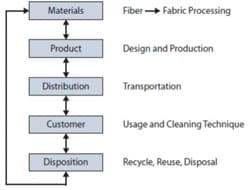

Explore the global impact of the textile industry.

Standard 1

Students will examine the sustainability concerns associated with textile production, use and care.

-

Environmental - practices and policies that reduces pollution and do not exploit natural resources

-

Social responsibility - The impact of textile production on people and communities

-

Economic

Standard 2

Student will differentiate between consumerism practices.

-

Purchasing considerations - Socially responsible buying

-

Care - Cleaning textiles with minimum environmental impact

-

Textile recycling/upcycling - Keeping textiles out of landfills

Strand 3

Analyze fabric and product production.

Standard 1

Understand that the type of yarn used has an important effect on the properties of fabric

-

Filament - strength, smooth, lusterous

-

Spun - generally weaker, dull, does not snag readily, resilient, absorbent

Standard 2

Students will review basic fabric construction (see prerequisite courses)

-

Woven fabric (denim, flannel, ripstop, neoprene)

-

Knit fabrics (Jersey, rib knit, fleece, polar fleece)

Standard 3

Students will classify non-woven fabrics and other materials

-

Non-woven - Any textile product that is created directly from fibers and is held together by bonding and entanglement

-

Other materials

- Leather - Hide of animal

- Down - Feathers

- Fiberfill - Synthetic material used for patting and insulation

- Netting - Yarns are fused, looped or knotted at their intersection resulting in a fabric with open spaces

- Fiber reinforced composites - High technology combination of textiles with resins, metals or ceramics (protective armor, helmets)

Standard 4

Student will describe fabric finishes.

-

Waterproof vs. water resistant - Completely moisture proof vs. withstands the penetration of water to some degree

-

Antimicrobial - Resistant to the growth of micro-organisms

-

Soil and stain release - Permits the relatively easy removal of soils, especially oily soils

-

Flame resistant - Slow to burn or self-extinguishes

Standard 5

Student will distinguish methods of printing and dyeing

-

Colorfast - will not bleed, fade, or crock

-

Dye classifications - A way of classifying the reaction between dye type and fiber

-

Screen printing - Pressing ink or dye through a screen with areas blocked off

-

Digital printing - ink jet-based method of applying colorant to fabric

Strand 4

Apply principles of the design process by reverse engineering a project.

Standard 1

Student will investigate design constraints and product purpose.

Standard 2

Student will analyze and compare suitable materials.

Standard 3

Student will calculate dimensions.

Standard 4

Student will select appropriate construction techniques.

-

Determine order of sewing operations

Step 1- Stitch darts, tucks, and pleats.

Step 2- Stitch style lines (any seam line besides shoulders, armholes, or side seams). Example: yokes and princess lines.

Step 3- Stitch or iron interfacing onto to all pieces needing it.

Step 4- Stitch pockets.

Step 5- Stitch zippers except a dress zipper.

Step 6- Stitch shoulder seams.

Step 7-Stitch side seams and inseams.

Step 8- Prepare collars. But don't stitch them in, yet.

Step 9- Prepare sleeves. Stitch plackets, cuffs, or elastic to sleeves and stitch underarm sleeve seam (if a set in sleeve). Don't stitch them in, yet.

Step 10- Attach collars.

Step 11- Stitch bodice facings.

Step 12- Set in sleeves.

Step 13- Attach bodice and skirt waistline if sewing a dress.

Step 14- Attach waistband or waist facing if sewing a skirt or pants.

Step 15- Stitch in dress zipper.

Step 16- Stitch hems.

Step 17- Stitch buttons and buttonholes

-

Consider necessary construction techniques for end use

Standard 5

Students will create adaptions and improvements to a product

Strand 1

Conduct an experiment that identifies the physical and performance properties of at least two natural and three manufactured fibers

-

Burn test

-

Microscope inspection

-

Absorbency test (water repellency spray test, water resistance impact penetration)

-

Abrasion test (sandpaper, pilling)

-

Hand and cover

Strand 2

Debate an issue regarding global impact of the textile industry

-

Sustainability

-

Fair labor laws

-

Fast fashion

-

Natural vs. manufactured (fibers, dyes, etc.)

-

Textile care (energy, water, chemical considerations)

Strand 3

Investigate a variety of multi-layer products to determine materials used

Strand 3

Experiment with fabric finishes

Strand 4

Create a soft goods project through reverse engineering

Workplace Skills

Students will develop professional and interpersonal skills needed for success in the fashion industry. Determine the difference between hard skills and soft skills.

- Hard Skills: Hard skills are specific, teachable abilities that can be defined and measured

- Soft Skills: Personal attributes that enable someone to interact effectively and harmoniously with other people.

Identify soft skills needed in the workplace

- Professionalism

- Respect Legal requirements/expectations

- Good communication skills

- Resourcefulness

UTAH EDUCATION NETWORK

UTAH EDUCATION NETWORK

Justin

Justin Braxton

Braxton Dani

Dani Kayla

Kayla Katie

Katie Lora

Lora Rob

Rob Val

Val